Utilizing DFAM to redesign a gearbox for The University of Texas at Arlington’s ROVER team.

The ROVER arm utilized gearbox’s made out of box tubing that had the following problems leading to chronic unreliability: high worm gear shaft deflection leading to skipping, difficult to assemble worm gear support, and a poor motor mounting solution.

See the full paper below for more information.

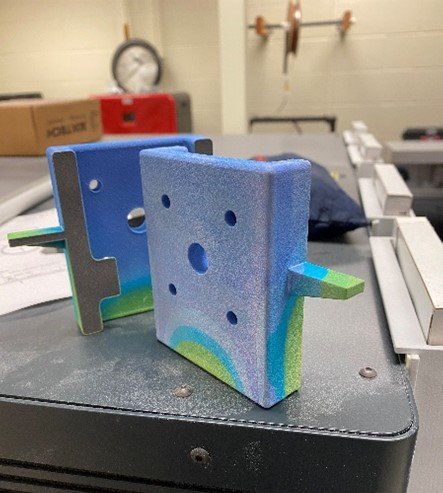

The FEA deformation results were mapped to the surface of the part using the 3mf file format.

FEA was used throughout the design process.

Multiple sub-assemblies were integrated into the MJF gearbox, such as the RJ 11 shelf.